- Based on standardized, pre-engineered modules to reduce CAPEX, optimize delivery lead time

- Simple to operate thanks to extensive automation options

- Complete performance guarantee with risk mitigation based on advanced dynamic modeling

- Safe, efficient training available via virtual plant simulation platform

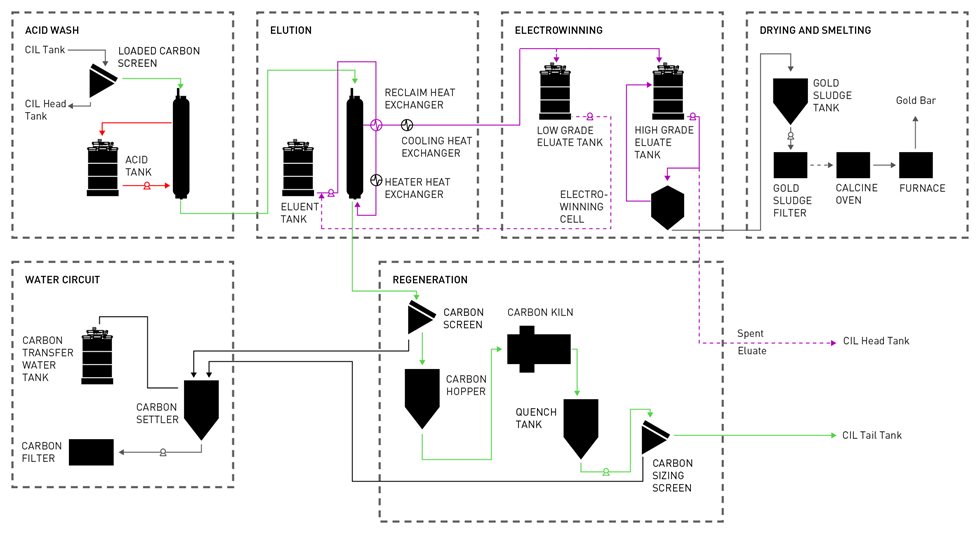

The Elution and Goldroom plant completes the CIL/CIP/CIC circuit, enabling stripping of gold from loaded carbon, electrowinning into gold sludge, and drying and smelting of sludge into doré bars. Carbon can then be reactivated for reuse in the circuit.

Metso’s turnkey process plant solution includes:

- Acid wash step to remove inorganic compounds from carbon

- Elution step to strip gold from loaded carbon

- Electrowinning to precipitate gold sludge

- Drying and smelting step to produce doré bars

- Regeneration step for thermal reactivation of carbon

- A dedicated water treatment circuit

Plant flowsheet designs