Outstanding spillage recovery

Used globally for recovery of spillage and return of it to the process eliminating mechanical recovery.

Robust design

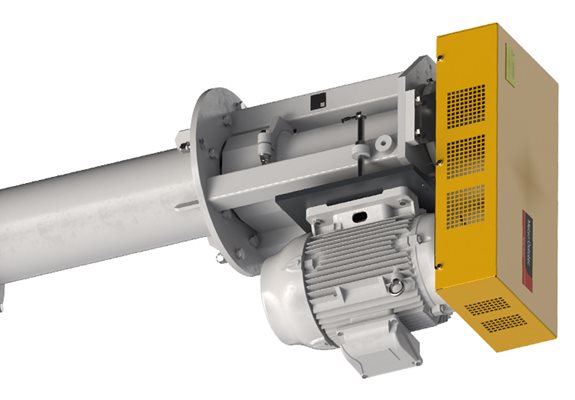

Cantilever design without submerged bearings or shaft seal.

Proven & most reliable

Proven for tough floor cleaning applications in mining concentrators.

Simple installation

Hang the pump in the sump by the lifting bracket provided.

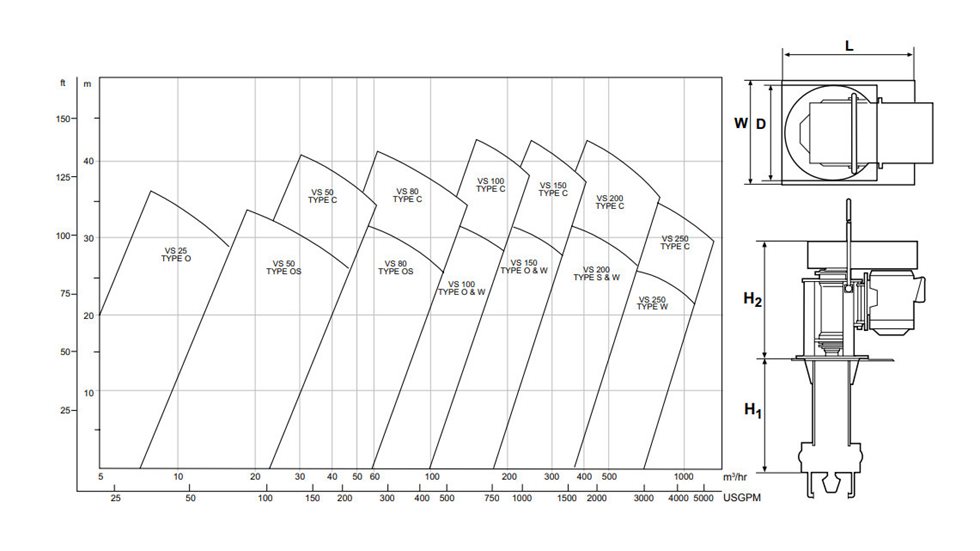

Metso Sala VS series vertical sump pumps are the strongest, high capacity and leading pumps preferred by the heaviest industries throughout the world. Globally used for efficient overflow recovery and its return to the process, our vertical sump pumps eliminate the need for mechanical recovery.

Developed from the old SALA sump pump, VASA G model, the Metso type VS vertical sump is the most reliable sump pump available on the market.

Industry's toughest, high capacity and leading vertical sump pumps

Sala VS series vertical sump pump benefits your process with these typical applications:

- Floor sumps in process plants

- Mill scale pumping in steel work

- Pumping of machine tool cuttings

- Wood chips pumping

- And many more

{{decodeHtmlEntities(field.label)}} |

|---|

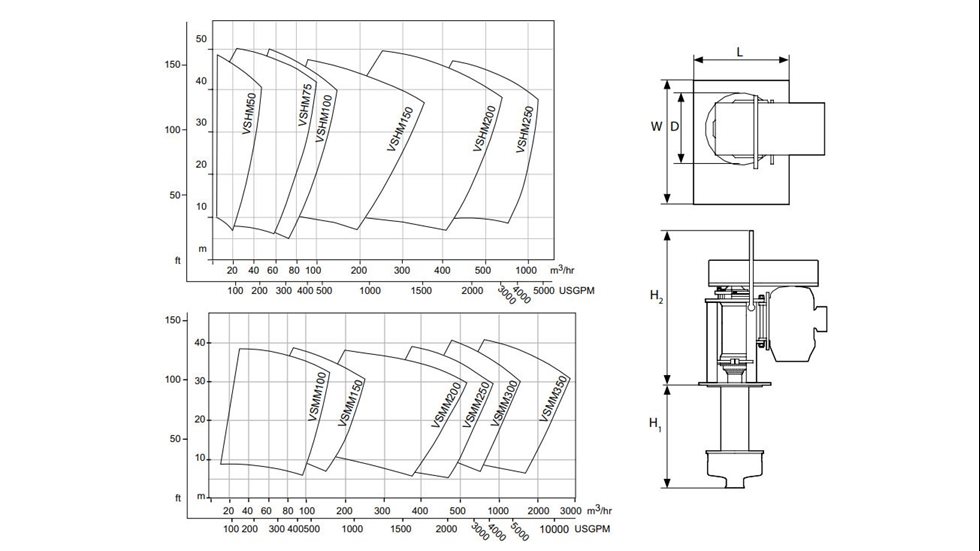

Sala VSH and Sala VSM pumps are a combination of the classic Sala VS sump pumps and Orion Series horizontal pump wet ends.

The combination provides a major advantage to the customer: the same wet end parts are used for both horizontal slurry pumps and sump pumps, thus reducing parts inventory and simplifying maintenance.

It also enables generating a higher TDH, pump head.

{{decodeHtmlEntities(field.label)}} |

|---|

{{decodeHtmlEntities(field.label)}} |

|---|