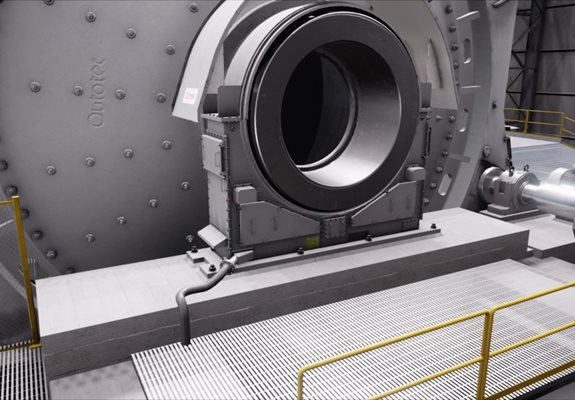

The Metso slurry wheel upgrade is a retrofit sealing solution for the grinding mill feed end. The existing configuration is replaced with a new and improved slurry return system featuring a unique water-wheel design that significantly improves the feed end material containment. More effective sealing helps to prevent excessive slurry spillage and reduces premature seal wear and its associated costs.

Reduce leakage, improve safety, and extend the seal service life

The Metso slurry wheel upgrade is a modernization solution that helps to maintain optimal grinding mill equipment performance and improve workplace safety. The proven design increases the grinding mill feed ends material containment.

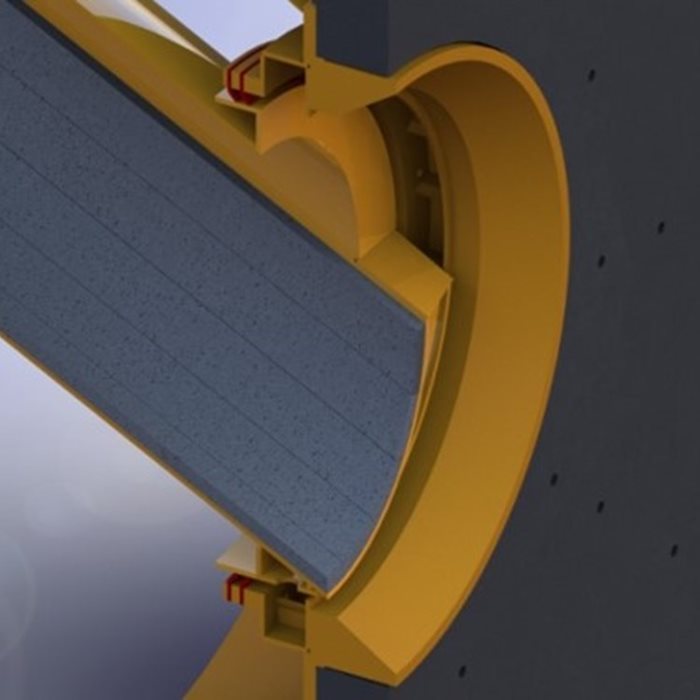

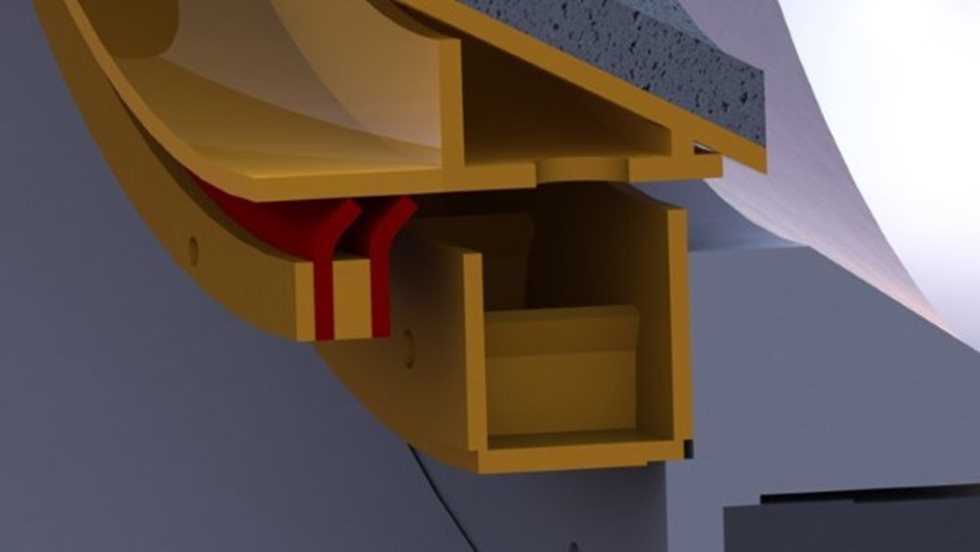

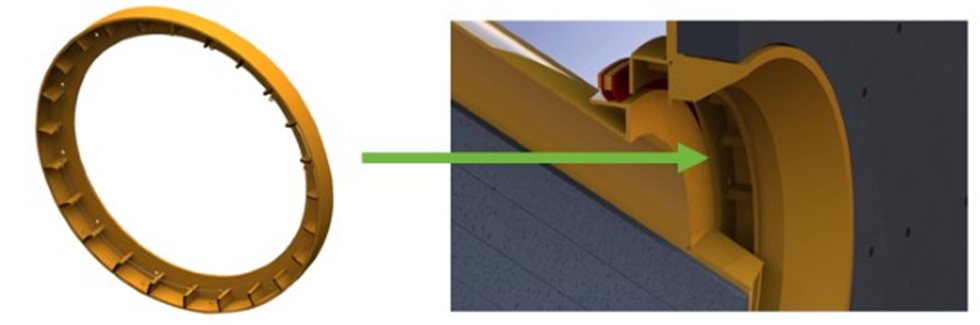

Our upgrade solution is ideal for existing mill installations that suffer from excessive slurry leakage. This can be caused by too high of a load on the sealing components, which leads to premature seal wear. With the Metso slurry wheel, the mill trunnion features a water-wheel type design, where any slurry flowing back through the trunnion is collected by buckets inside the wheel. The slurry is then deposited back into the feed spout before re-entering the milling chamber, thereby reducing the load on the sealing components.

Simple upgrade with minimal downtime

The upgrade process can be carried out on-site and requires only minor modifications to the existing feed arrangement. As with all retrofit installations, we recommend a site inspection to confirm that the existing feed sealing arrangement is in suitable condition for upgrading. This will reduce the risk of unforeseen problems during installation that may lead to extended plant downtime.

A customized solution for your mill

Metso experts will provide you with detailed feedback about any potential issues identified during the pre-design mill inspection. We will then design a custom slurry wheel assembly for your specific application.

We can also support you with a complete range of installation and commissioning services that will keep downtime to a minimum and ensure a smooth start-up.