Achieve improved stability and efficiency in your crushing and grinding process with Metso RockSense 2D™ high-performance measurement technology.

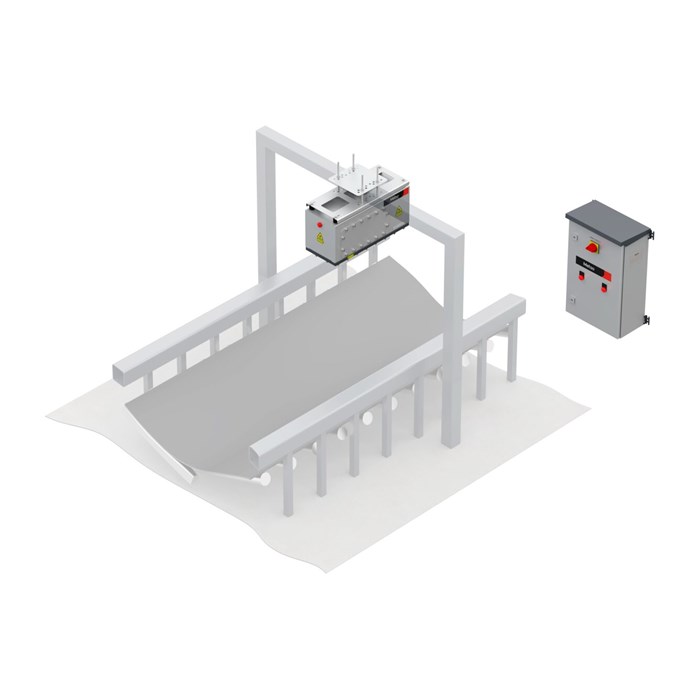

An online particle size analyzer system for rocks moving on a conveyor belt that uses 2D imaging technology.

Features:

- Online, continuous on belt coarse particle size distribution

- For control applications

- Based on camera technology

- Improved Image Miner

Take comminution optimization to the next level with better knowledge of particle size detection (PSD) on the belt.

Using 3D imaging: Accurate, continuous on belt coarse particle size distribution and volume flow. AI / neural network capability for foreign objects and oversized lumps detection.

Features:

- Online, continuous on belt coarse particle size distribution

- High accuracy and control applications

- Uses high-performance 3D imaging technology

- Cumulative volume flow estimation (m3/h)

- AI / deep learning capability, for example of foreign objects recognition and oversized lumps detection

- Improved image miner