Improving process stability

- Stabilized flotation process with variable feed grade

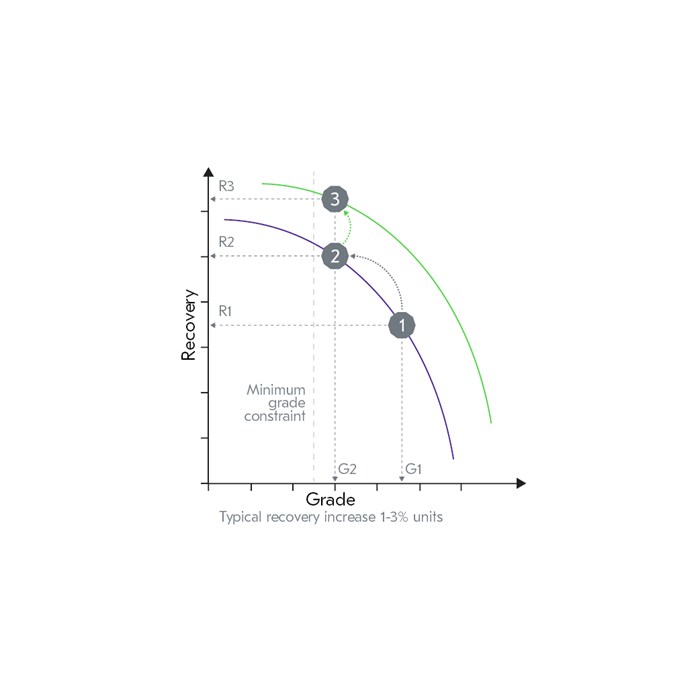

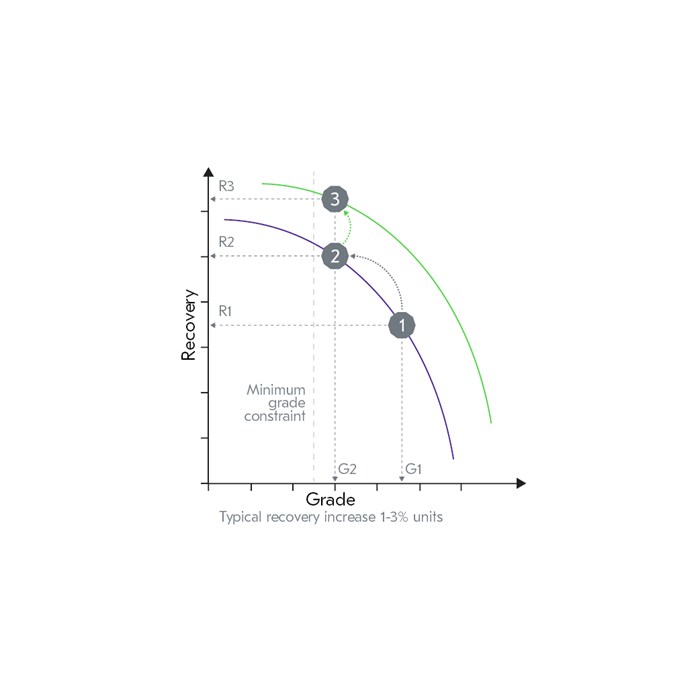

- Increased recovery with optimal grade

- Reduced reagents consumption and costs

- Free up operator time for fine-tuning of the process

- Improved function of downstream

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Improving process stability is the key to successful and effective flotation process control. For example, when the feed grade and ore properties change, timely adjustments are needed to maintain a stable process. When the process is stable, tighter margins can be maintained and run the process closer to target. The result is higher recovery with same grade because of operating more at optimal process area (less turbulence, more constant mass pull, optimal use of reagents, faster reaction to head grade changes, etc.)

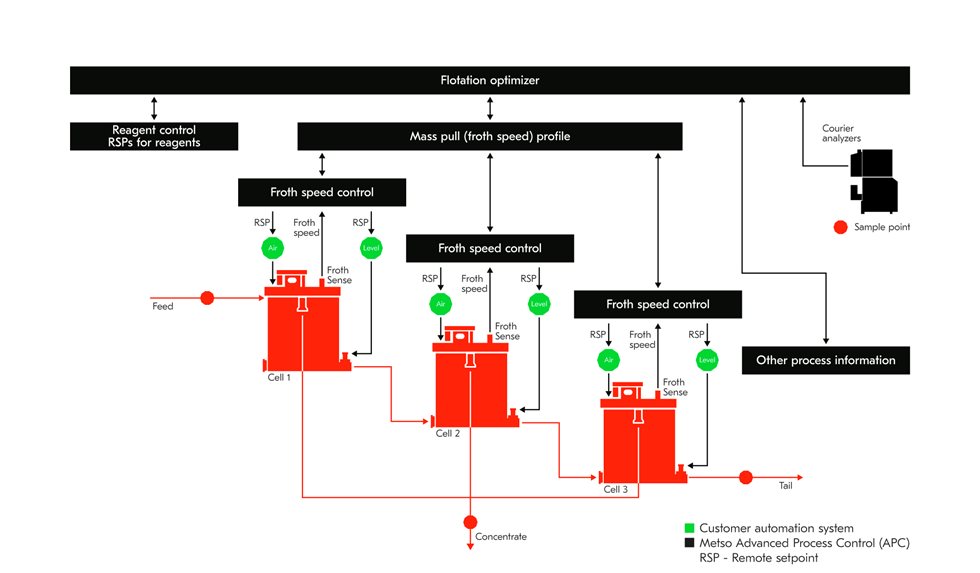

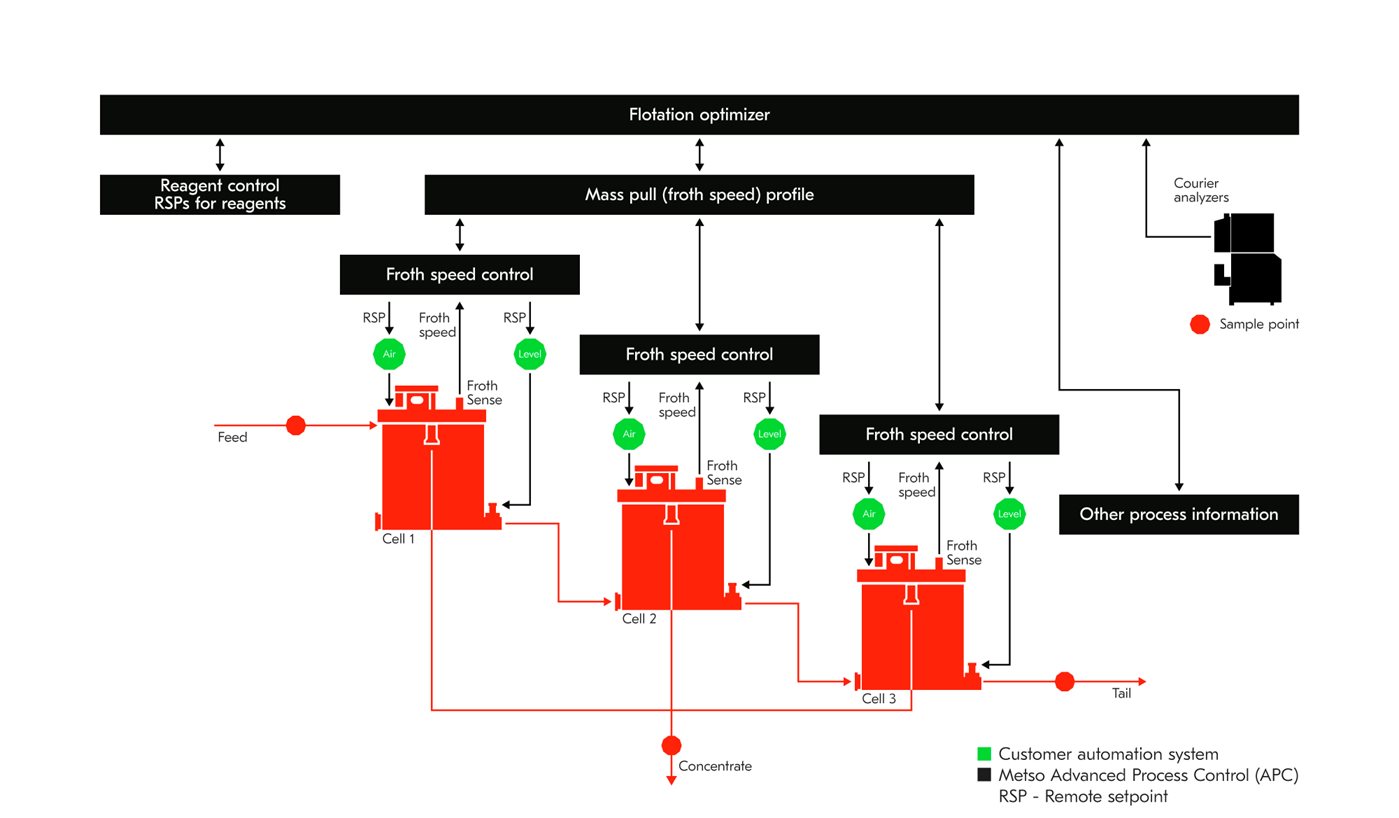

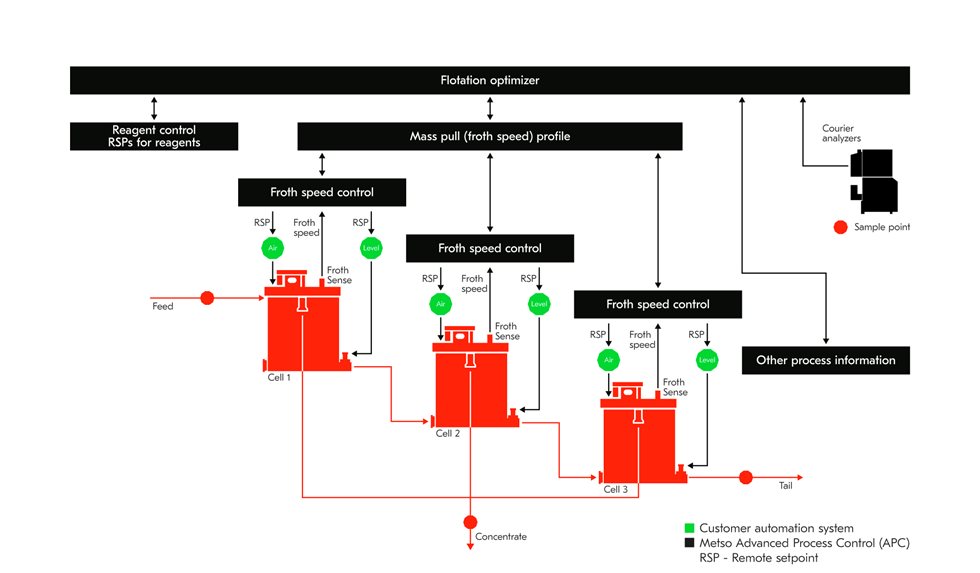

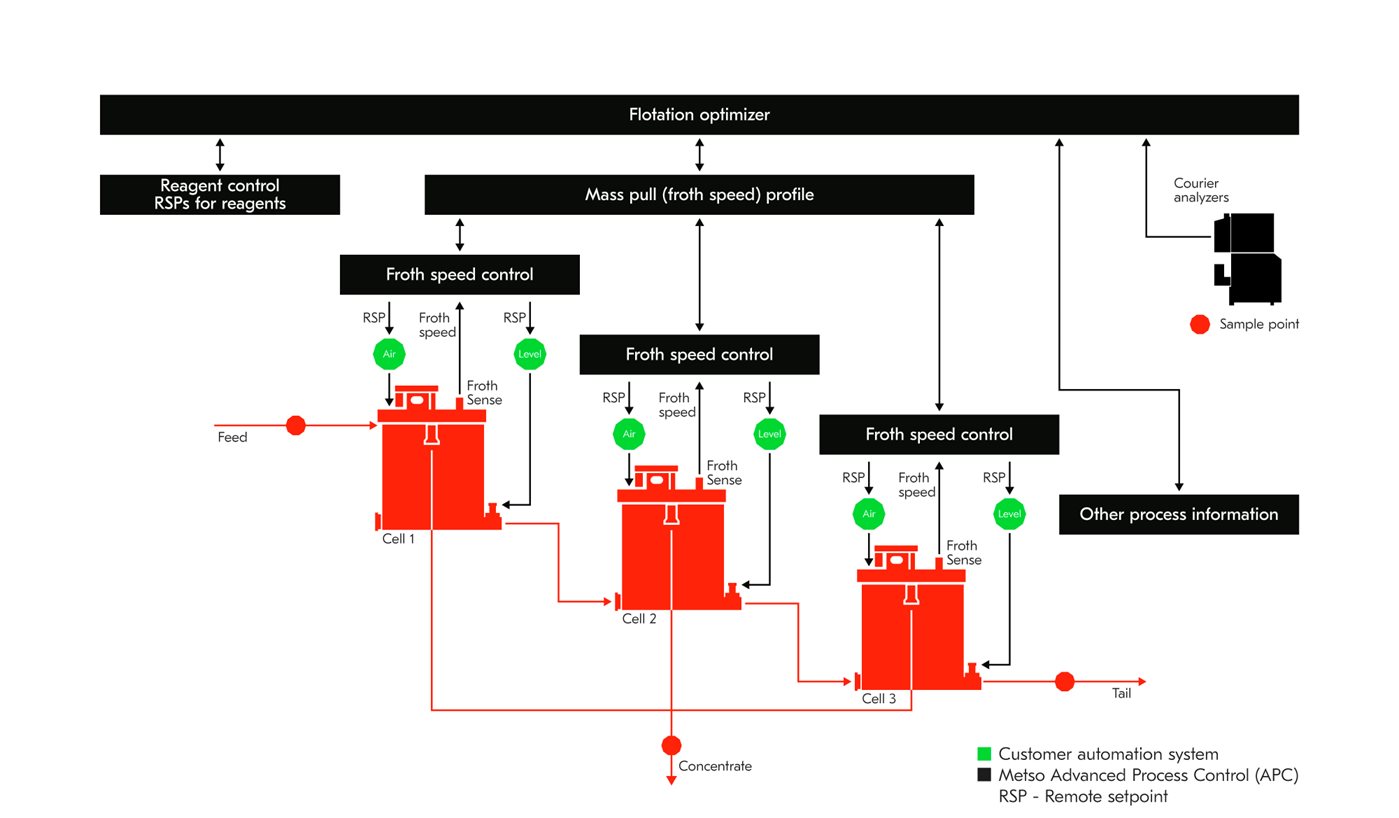

The Flotation optimizer utilizes on-line elemental measurements (Metso Courier) available from the process and manipulates the mass pull and reagents.

Controlled variables typically are:

Traditionally mass pull has been adjusted by changing aeration rate and/or slurry level. Because the froth velocity (Metso FrothSense) has been proven to be a good indicator for the mass pull of a flotation cell, the Flotation optimizer will manipulate the setpoints of froth speeds instead of air and level control loops.

Depending on the level of optimization, Flotation optimizer can be implemented either for a single part of the process (rougher/scavenger, cleaner circuit) or for the whole flotation process. If the process is large and involves a lot of feedback loops, the best benefit is achieved by splitting and building a dedicated Flotation optimizer for each.

The control strategy is always customized for the customer’s specific flotation process. It combines customer experience with Metso know-how of multiple flotation processes.

The Flotation optimizer is based on proven proprietary APC platforms and is built by using Model predictive control (MPC) algorithm.