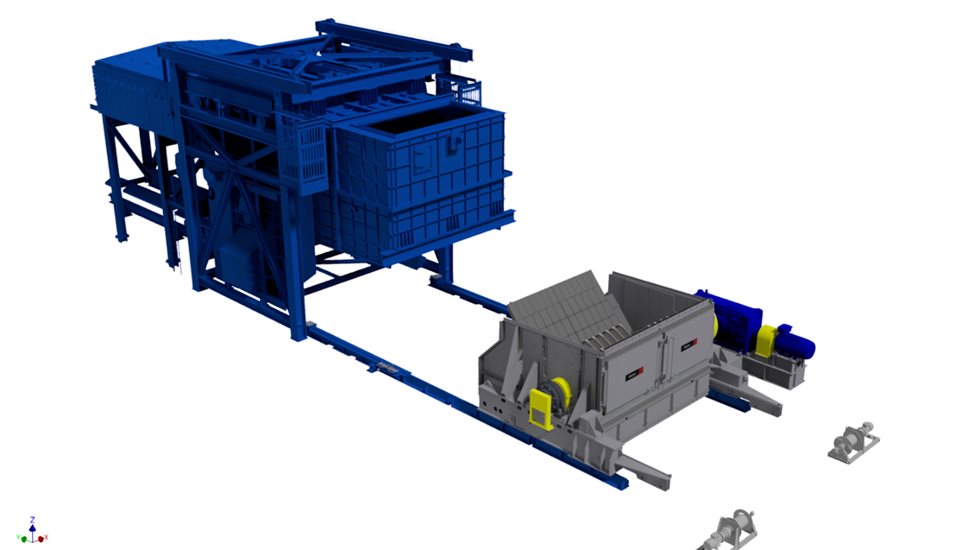

Metso always aims to provide a proprietary and best-in-class design for the process-relevant key equipment, with a special focus on efficiency, reliability, longevity and maintainability. Thus, for our sinter plants, we improved the design of the sinter breaker by adding the possibility to move the complete sinter breaker assembly out of the discharge casing, into a safe and accessible maintenance space. In addition to that feature, the grizzly bar carrier is movable for easy access to the grizzly bars.

Movable Sinter Breaker

Reliable performance & easy maintenance

The hot sinter cake falls onto the crush deck of the sinter breaker during the lowering movement of the pallet car at the tipping station of the travelling grate. The sintered material is partly still burning with an average temperature of 800 °C. The function of the sinter breaker is to crush the hot sinter cake into smaller chunks. High temperature abrasion takes place and leads to intensive wear on the rotating crusher stars and the grizzly bars. To extend the service life, sophisticated hard facing is applied for the rotating stars and the grizzly bars. The crush deck is lined with ceramic and NiHard blocks. Besides the wear protection, it is essential to maintain highly stressed parts. Therefore, the maintainability has been a key focus for the design of the new sinter breaker.

A newer sturdy design

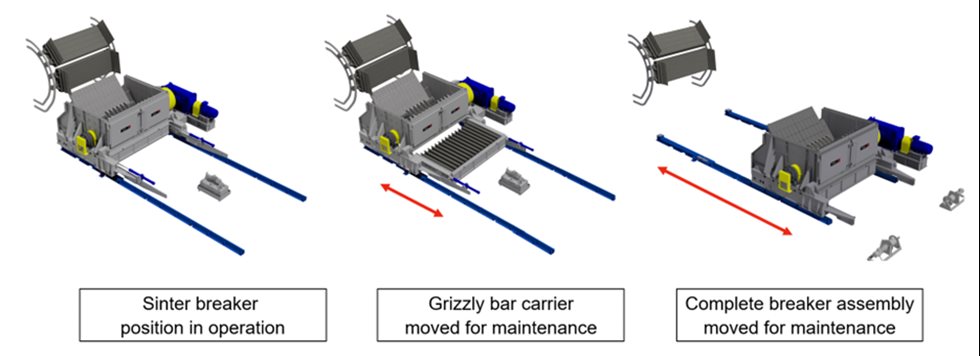

After several tons of crushed sinter, even the sturdiest wear protection requires maintenance. Reconditioning by hard facing must be done during the maintenance downtime. Yet sometimes, parts like the shaft/star assembly or the crush deck require replacement. In order to limit the downtime, it is important to do the maintenance work as effectively as possible.

The following features are implemented into the design:

-

The grizzly bar carrier is movable to ease access to the grizzly bars

-

The complete sinter breaker assembly is movable via winches to ease maintenance work

-

The retracted maintenance position of the sinter breaker enables the replacement of the shaft/star assembly and the crush deck

-

Crush deck and shaft/star assembly are designed for easy replacement

-

Metso design complies to IS/ISO (Mechanical) & IS/ IEC (Electrical) Standards & Codes, ensuring quality and reliability in every aspect.

The new sinter breaker is considered in Metso’s standard set-up for 4-meter-wide greenfield sinter plants, but it can also be delivered as an upgrade in most cases where aged breaker assemblies need to be replaced in existing plants.