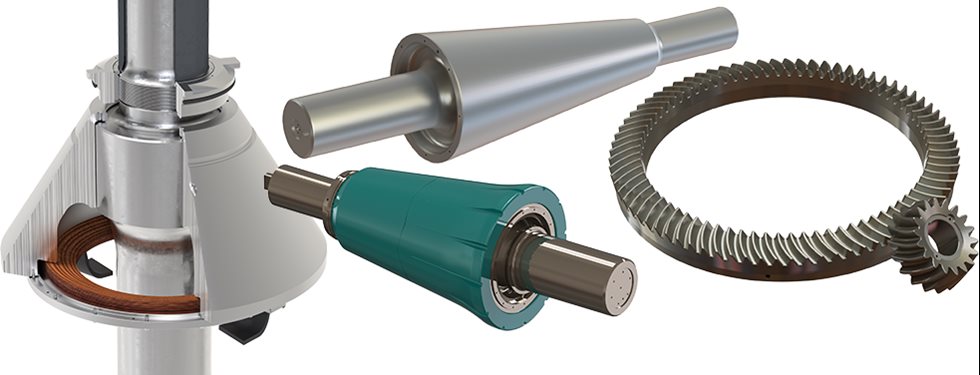

In today’s mining industry, the crushing sector thrives on innovation – an area where Metso has a long history of advancements. As a leading provider of comprehensive crushing solutions, Metso has consistently delivered exceptional value to its customers. Boasting the largest installed base of crushing equipment, we saw an opportunity to utilize our breadth of knowledge to support our customers that extra mile.

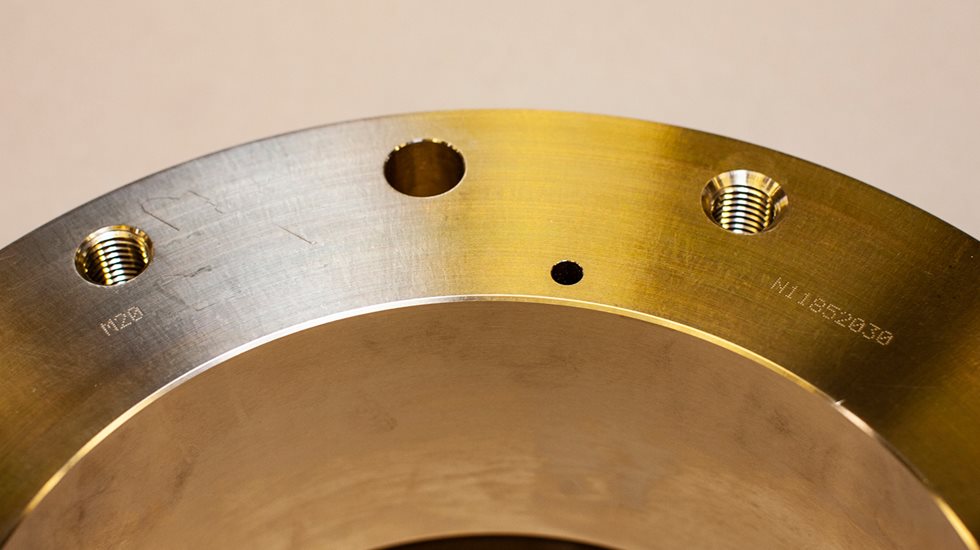

Contender™ Series is a relatively new quality part offering made for non-Metso crushers. These parts are engineered to seamlessly fit and perform with premium third-party crushers from brands such as Sandvik, FLSmidth and ThyssenKrupp.

“Contender Series was established to fill in the gap,” says Mikko Harakkamäki, Global Product Manager, Contender Series Spares. “Customers know our history with their crusher models, and they were coming to us for an offering – so we created our own.”

Contender™ Series not only brings improved safety features and extended operational life, but also highlights the significance of using a company with OEM know-how. With a wide global presence, unrivaled availability and a commitment to sustainability, this offering allows customers to experience the unparalleled support and service that Metso can provide.

“By also supporting 3rd party equipment, we step away from being ‘just a part provider,” says Mikko. “We can now truly work as partners and solution suppliers, and provide next-level parts and support to our customers even when their machines are not 100% Metso.”

By addressing vulnerabilities and ensuring the protection of critical components, Contender Series delivers high reliability and prolonged operational performance. Read more below on a couple of common challenges within the industry, and how Contender Series solutions can elevate your equipment.