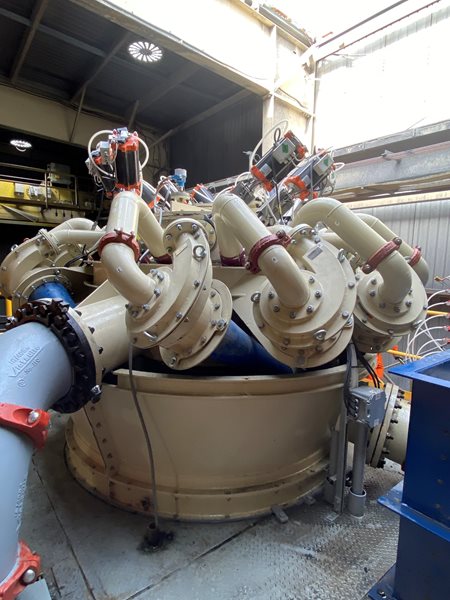

Why choose incline installation?

-

Most obvious – space constraints. In an existing concentrator plant, the building footprint and height are already set. Hydrocyclones typically sit at the top of the grinding or filtration circuit in the concentrator plant, and so any new hydrocyclone cluster must fit into the available head height. Designing the cluster with inclined hydrocyclones would eliminate some extra height that would be there compared against a hydrocyclone cluster with vertically-installed hydrocyclones. If no additional retrofit work is required to install this new hydrocyclone cluster into the existing space, this would be cost savings.

-

Increase the cut size - One would consider operating a hydrocyclone at an angle to increase the cut size. The gravity coefficient pulling particles to the underflow is not as strong when operating a hydrocyclone at an angle, and so the operating pressure coefficient is able to overcome gravity and force some larger middling particles to overflow.

-

Decrease the fines bypass - A decrease in fines bypass can also be a result when operating a hydrocyclone on an incline. In addition to the larger middling particles, the pump pressure will “push” more water to the overflow compared against a vertically installed hydrocyclone. Fine material will report with the water.

As a negative, a reduction in separation efficiency can occur when operating at an angle. Instead of fine particles incorrectly reporting to the underflow, coarse particles can incorrectly report to the overflow. This might not be detrimental to hydrocyclone performance but instead is something to be aware of and monitor.