The mining industry has performed poorly compared with other industries in terms of project overspend. Capital cost overruns have been a consistent feature of mining projects for decades, with average overruns of 20–60% since 1965. Our customers and EPCMs are increasingly seeking alternatives to traditional project execution models to reduce the project-related risks.

At Metso, we have focused on developing predesigned, modular unit process island offerings around our proprietary equipment and key technology areas, as well as developing extensive complementary digital offerings for the most critical hydrometallurgical unit processes.

This plant unit approach is nicely in line with the traditional EPCM model, allowing EPCM companies to have more standardized and proven building blocks to allow faster and more predictable completion of the overall plant design, project execution and plant ramp-up. Our lifecycle service solutions are built into these plant unit offerings to help our customers to optimize production and secure availability of these core unit processes.

This model brings the following benefits:

- Improved clarity and simplified project management with one supplier responsible for the most critical key hydrometallurgical unit processes

- Reduced risk through more predictable delivery and fabrication of key unit processes

- Customer can focus on their core business

- Reduced overall project duration

- Lower total installed cost

- Increased safety and improved quality with more work done at the workshop and less on site

- Increased predictability in terms of schedule and costs

- Earlier production by improved net present value (NPV)

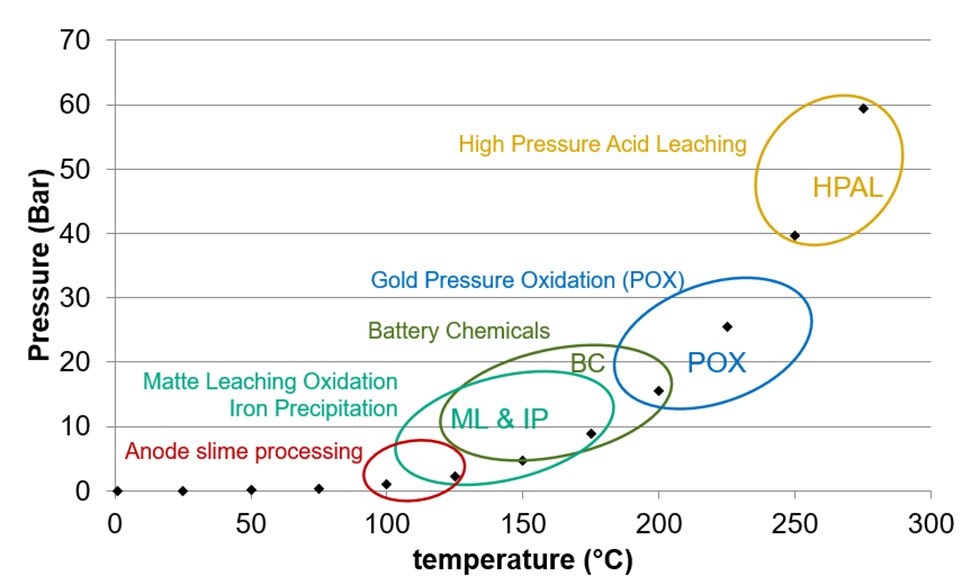

Below are some examples of our hydrometallurgical plant unit products that are built around our proven proprietary process equipment and technologies.

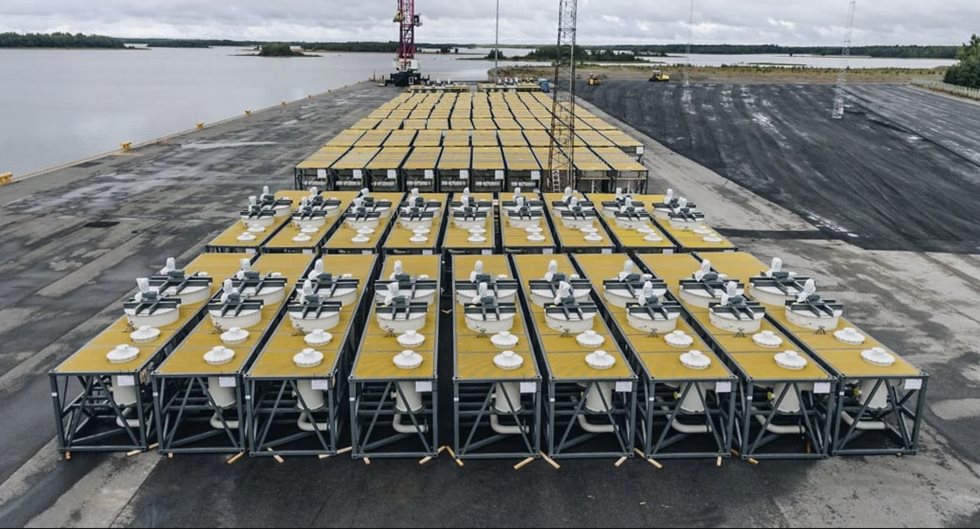

Metso VSF® X – Modularity for solvent extraction plants

The Metso VSF X plant is an example of International Mining Technology Hall of Fame recognized revolutionary modularity in hydrometallurgy. The plant provides a novel way to design, manufacture, transport, install, operate and maintain a solvent extraction (SX) plant. The elegance of the modular product lies in the use of productized settler modules, which enables the construction of a settler consisting of independent sections. Our renowned SX expertise is built into these modules, which are fully suitable for intermodal transportation as standard freight containers. The modules are procured, manufactured and transported via a predefined supply chain, enabling more reliable and faster delivery. This supply philosophy provides the flexibility for custom designed SX plants built from standard modules to enable faster, safer and more economical project implementation. The benefits of VSF X have already been proven in several customer projects.

Modularization continues to become more popular with benefits including a reduction in costs and time spent, but most importantly the creation of a safer working environment.