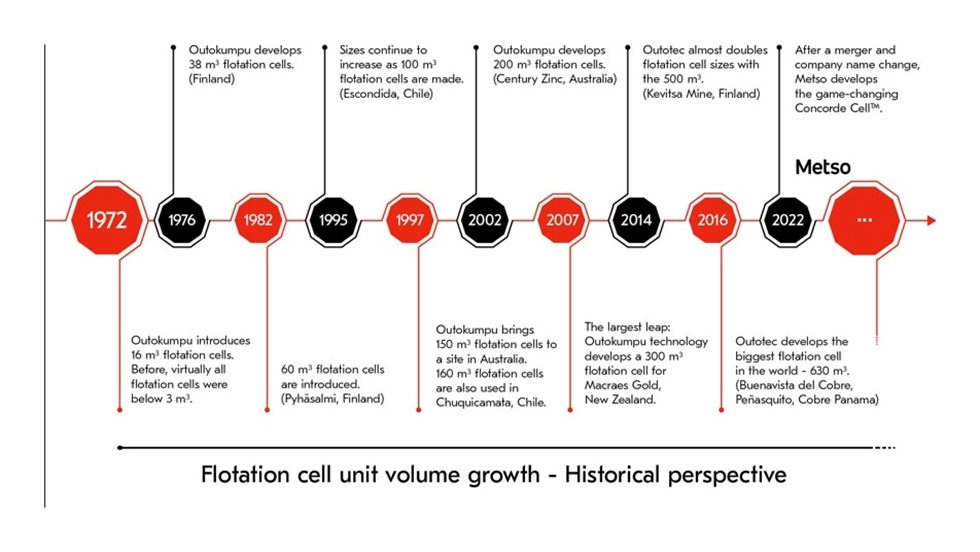

Here at Metso, flotation technology has played a pivotal role in our history for over five decades. Evolving from humble beginnings at Outokumpu – and then further developed by Outotec – flotation has become one of the most critical phases of mineral processing operations.

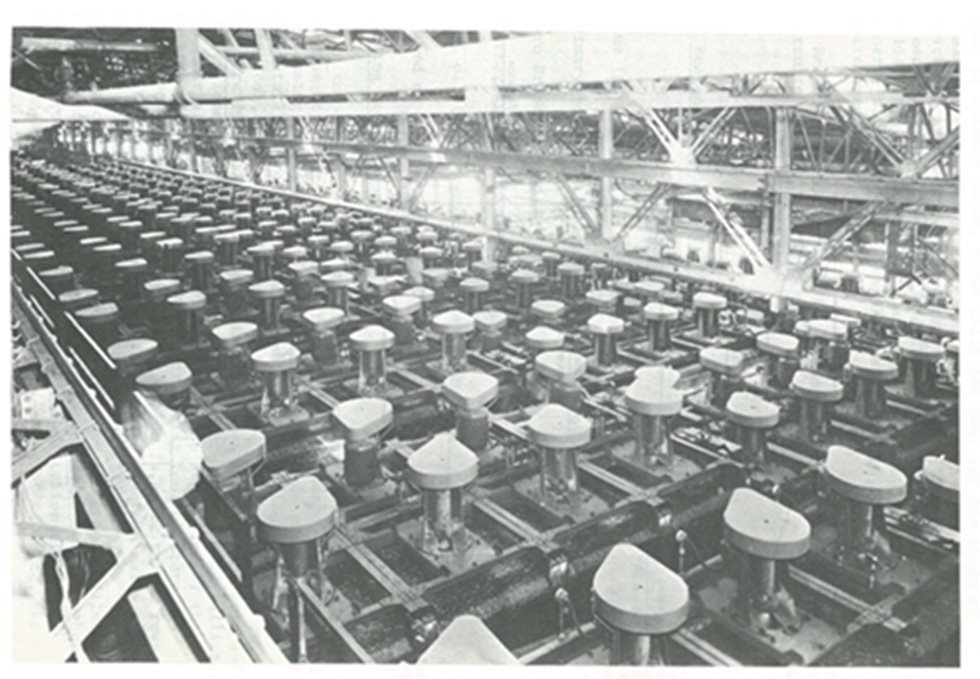

In the 1970’s, Outokumpu – a world class mining company whose technology unit would eventually become Metso – was expanding their mines. When doing so, they realized that the flotation cells available at that time, which were maximum 2 or 3 cubic meters in size, were not big enough for their operations. Naturally, they decided the only way to get such large and reliable processing equipment is to develop it themselves. So, they did - and large flotation cells entered the market, revolutionizing the way valuable minerals are separated from ore.

“It’s funny because in those days, there were articles written about how Outokumpu has developed something so big and unnecessary that nobody else will ever actually need or use it at all,” says Antti Rinne, VP, Flotation at Metso. “But eventually, mines started to process bigger tonnages and as an outcome, needed that bigger equipment – and Outokumpu was the only company selling these sizes. At that time, it was a very new market.”

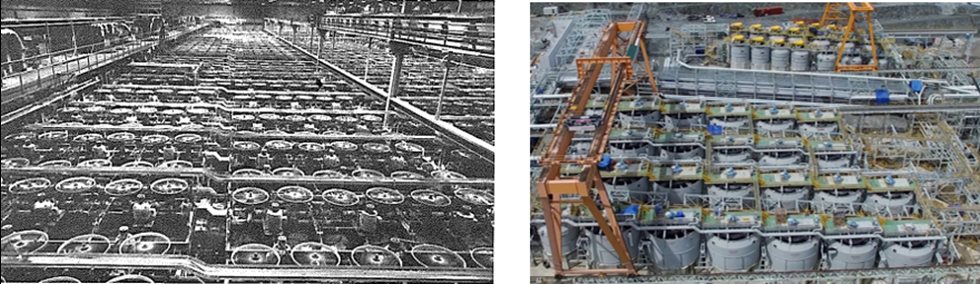

Since then, the industry’s use and perception of flotation technology, as well as its place in the flowsheet, has evolved. Outokumpu's foresight proved visionary as mining operations and the tonnage of processed materials were growing at an exponential rate.

Over time, declining ore grades and the need for higher production had driven the industry to adopt larger and more efficient flotation equipment. Since valuable materials became scarcer within ore deposits, mining companies were forced to process larger quantities of ore to maintain production levels.

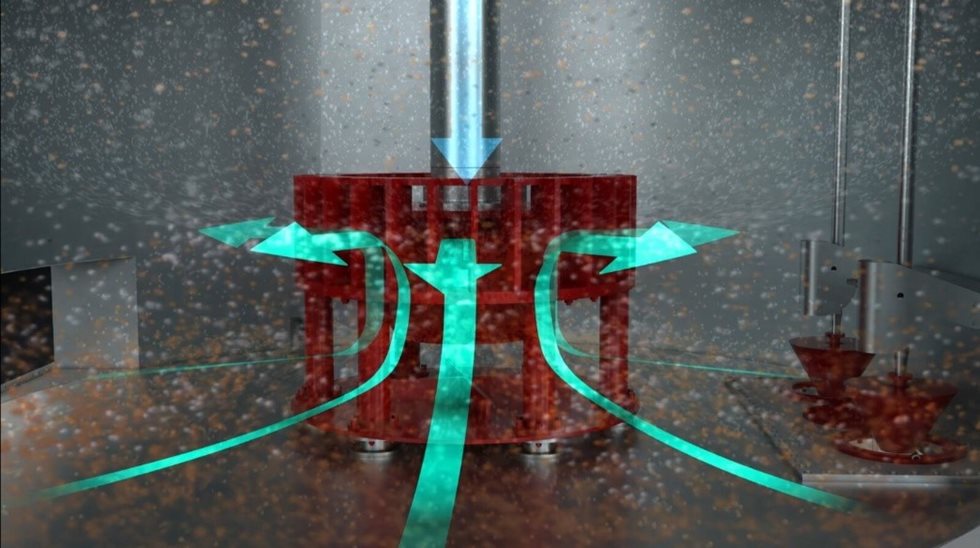

Throughout 50 years, environmental considerations and the pursuit of energy efficiency has also become paramount in the mining sector. In response to this evolving landscape, Metso has developed innovative solutions that not only enhance performance but also contribute to sustainability goals.