Metso Outotec expands battery chemicals filtration offering with modular DM1000 polishing filter

Metso Outotec Corporation’s press release on October 12, 2021, at 09:00 a.m. EEST

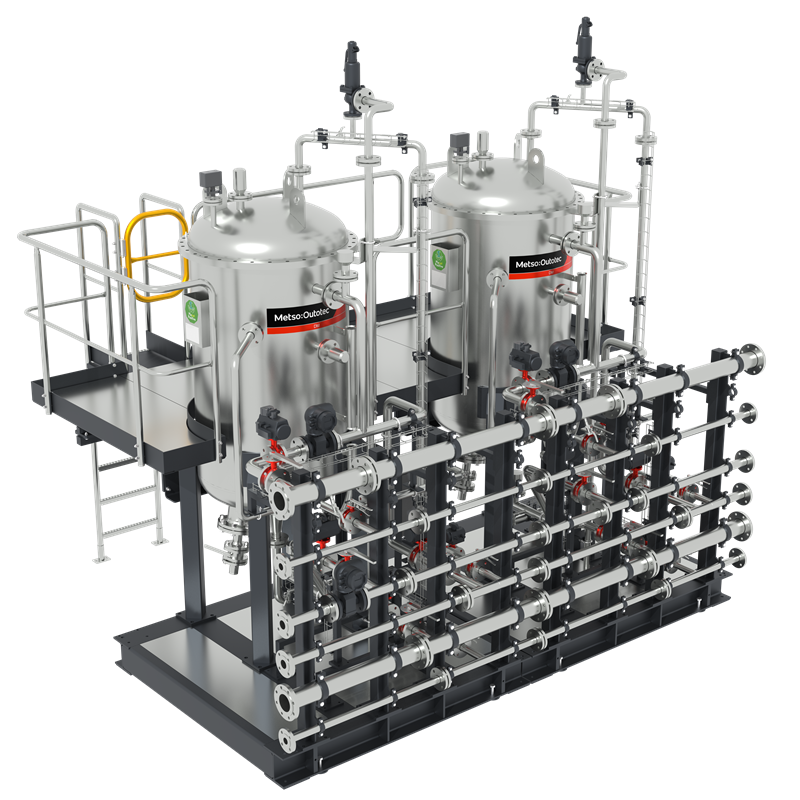

Metso Outotec is introducing a new modular filter to its Dual Media (DM) filter product family. The compact Metso Outotec DM1000 polishing filter is particularly suitable for removing and recovering organic compounds and solids in small stream feeds in battery chemicals processes. Thanks to its modular design, the filter is easy to expand also for larger process flows.

The DM1000 can be used as a traditional electrolyte filter in the extraction processes as well as for feed flow purification before crystallization in the metal crystallization processes.

“Since the launch of our first Dual Media filters some years ago, we have delivered almost 50 DM and DM AC filters for hydrometallurgical extraction and crystallization processes. We have delivered hundreds of polishing filters to the mining, chemical, and hydrometallurgical industries around the world,” says Mika Vuorikari, Director of industrial filtration at Metso Outotec.

“Adding the modular DM1000 filter to our offering caters to the special needs of the rapidly growing battery industry, where sustainable high-quality filtration is needed to ensure increased production capacities and high-quality end products,” elaborates Vuorikari.

The energy- and water-efficient Metso Outotec DM1000 polishing filter for battery chemicals is part of the company’s Planet Positive offering.

Benefits:

- Low energy consumption, thanks to low pumping pressure

- Reduced water consumption, thanks to back wash with filtrated process liquid

- Efficient recovery of organic compounds back to process

- Easy expandability with the compact, fully modular design featuring 1-4 filters in a row

- Easy transport, as filters can be packed and transported in standard sea containers

- Quick and safe site installation as the filter comes ready assembled on a mounting skid

- Fully automatic operation contributes to overall safety

Discover more about the Metso Outotec DM1000 filter on our website.

Metso Outotec provides technology and equipment for the entire lithium, nickel, and cobalt production chain – from the mine to battery materials – with a project scope ranging from equipment packages to plant solutions delivery.

Further information, please contact:

Timo Jauhiainen, Product Manager, Filtration, Metso Outotec, tel. +358 20 529 4384, email: timo.jauhiainen(at)mogroup.com

Helena Marjaranta, Vice President, Communications and Brand, Metso Outotec, tel. +358 20 484 3212, email: helena.marjaranta(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.